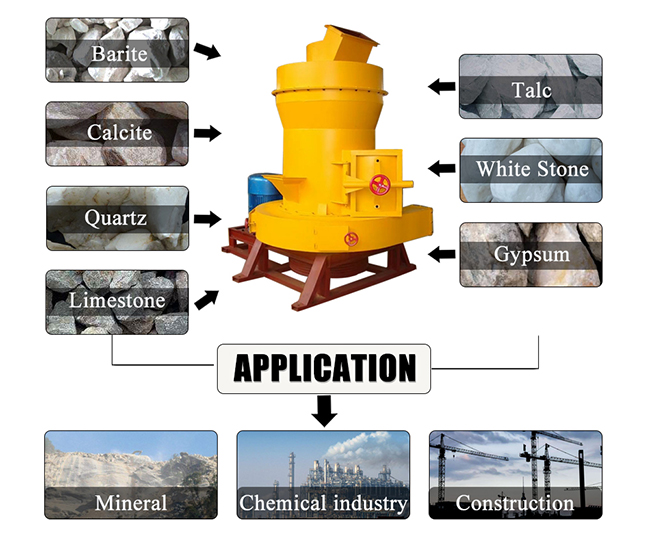

Raymond mill is commonly used in milling equipment, mainly for barite, calcite, potash feldspar, limestone, talc, white stone, gypsum and so on. The application of Umo hardness is not greater than 9.3, humidity in less than 6% of the inflammable and explosive mineral products, chemicals, building materials and other hundreds of kinds of materials of high fine milling processing, product granularity in 40-400 of the scope of arbitrary adjustment.

The series of products for different materials, different fineness, different output requirements, divided into high-pressure micro-grinding, pressure suspension roller mill, General Raymond Mill three series of more than 10 models.

Working principle

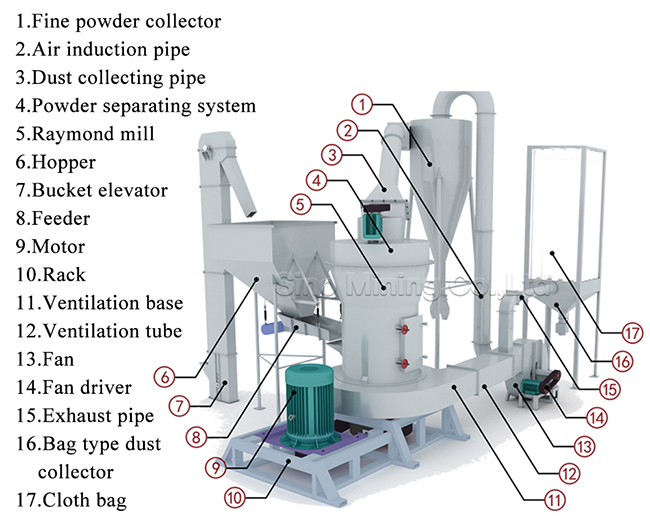

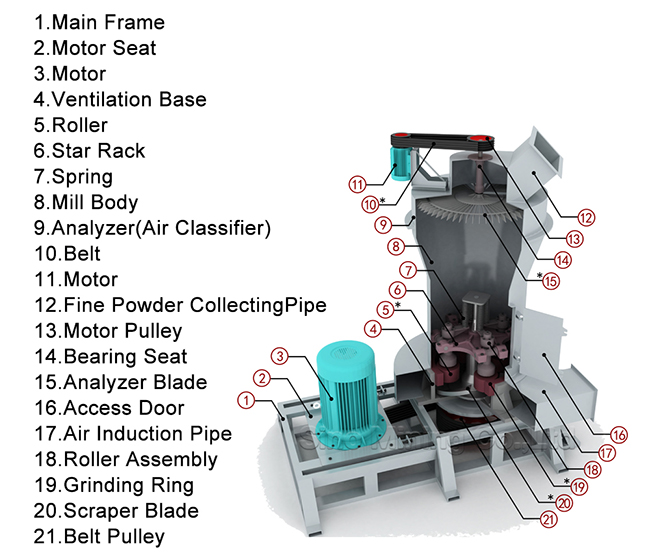

The work principle of Raymond Mill is that the roller is rolled tightly in the grinding ring under the centrifugal force, shovel from the shovel material to the grinding rollers and grinding ring, the material under the action of crushing into powder, and then in the role of the fan into the powder blown up through the analysis machine, to achieve fineness requirements of the material through the analysis machine, Can not reach the required return grinding cavity to continue grinding, through the analysis of the material into the cyclone separator collection. The exhaust air is separated by industrial filter cloth to form a powder.

1、complete sets of strong, from the block expected finished powder from the independent production system.

2、The finished powder fineness uniformity, the pass sieve rate 99%, this is other grinding equipment is difficult to have

3、The transmission device of Tenremont Mill adopts closed gear box and pulley, stable transmission and reliable operation.

4、Important components are high-quality steel, wear-resistant parts are high-performance wear-resistant materials, the machine wear-resistant, high performance, reliable operation

5、Raymond Mill Electric system using centralized control, milling Workshop can achieve the basic unmanned operation, and easy maintenance

Return

Return